Aluminum Composite Panels (ACP) on buildings

|

Contents |

[edit] Introduction

Aluminium Composite Panels are made by laminating an intermediate layer of non-aluminium core between the top and bottom layers of a thin aluminium panel. ACP panels can be further coated with Polyvinylidene fluoride (PVDF) or polyester paint. Total thickness of panels varies from 3 mm to 6 mm, including adhesive layers and glues.

ACP panels are used on the interior and exterior of buildings, often with coloured finishes.

[edit] Features of ACP panels

Aluminium Composite Panels (ACP) offers a wider range of options for builders and architects:

- Durability: ACP laminate is weather resistant, stain resistant and highly durable. Even after exposure to sunlight and weather changes, the panels retain their colour, shape and size, making them ideal for all seasons. They are also soundproof, allowing sound to be deducted from the outside environment.

- Safe to use: Because aluminium is a very good insulator, ACP panels are fire resistant. They do not emit gases or fumes and are safe for internal cladding.

- Economical: Aluminium composite panels are one of the most cost effective and economical materials on the market. They are easy to use, durable and provide the perfect answer for commercial establishments. According to experts, ACP panels offer high quality thermal comfort and reduce energy consumption, thus reducing your electricity bill. They can be used in a variety of shapes and sizes, minimising waste.

- Hassle-free installation: ACP laminates are easy and undemanding to install and can create some extraordinary designs that may be difficult or impossible to recreate with other materials.

- Easy to maintain: ACP laminates require low and hassle-free maintenance and will retain their shape and texture for a long time. Dirt or dust particles can be removed from its surface by simply wiping with a cloth.

[edit] Advantages of using ACP sheet

Below are some of the main advantages:

- The panel has the qualities of light weight, durability, rigidity and strength.

- Another added benefit is its strength-to-weight ratio.

- ACP panels can be cut into various sizes to suit your requirements and the material is highly adaptable.

- The PVDF coating makes it fire and weather resistant, protecting the material from fading and staining.

- ACP panels have a perfectly uniform surface without any deflection or distortion and are resistant to breakage.

- These panels are easy to install and maintain, easy to recycle, and therefore environmentally friendly.

- Aluminium composite panels provide excellent thermal and acoustic insulation.

- They are also weather resistant and UV resistant.

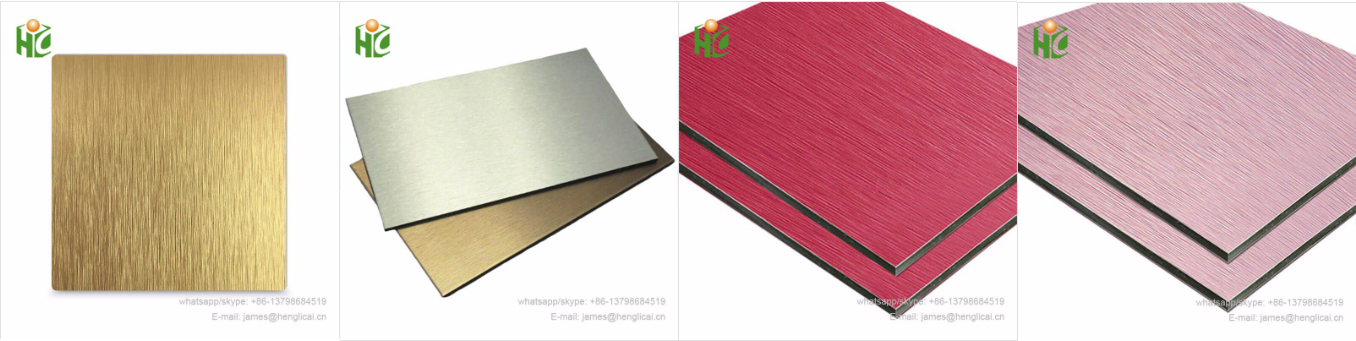

- These panels are available in a wide range of colours and finishes, from standard colours to high-gloss, matte and metallic finishes.

[edit] ACP Sheet Applications

ACP is an important part of the interior and exterior decoration of hotels, hospitals, subway stations and other buildings, were it can be uses as:

- Exterior and interior of buildings and corporate housing

- Cabinets, closets and modular kitchens

- False ceilings

- Wall panels

- Machine and equipment coverings

- Signs and signage

- Container construction

NB Click here for information about ACM cladding and the Grenfell Tower fire.

[edit] Related articles on Designing Buildings

- ACM cladding.

- Aluminium.

- Aluminium decking.

- Cast iron.

- Copper.

- Difference between cast iron and wrought iron.

- Failure of metals.

- Flashing.

- Galvanised steel.

- Iron.

- Lead.

- Lead in construction.

- Major cast metal components.

- Metal.

- Metal composite panels.

- Metal fabrication.

- Metal roofing.

- Potash.

- Stainless steel.

- Structural principles.

- Structural steelwork.

- Types of metal.

- Types of steel.

- Weathering steel.

- Zinc.

Featured articles and news

Gregor Harvie argues that AI is state-sanctioned theft of IP.

Many resources for visitors aswell as new features for members.

Using technology to empower communities

The Community data platform; capturing the DNA of a place and fostering participation, for better design.

Heat pump and wind turbine sound calculations for PDRs

MCS publish updated sound calculation standards for permitted development installations.

Homes England creates largest housing-led site in the North

Successful, 34 hectare land acquisition with the residential allocation now completed.

Scottish apprenticeship training proposals

General support although better accountability and transparency is sought.

The history of building regulations

A story of belated action in response to crisis.

Moisture, fire safety and emerging trends in living walls

How wet is your wall?

Current policy explained and newly published consultation by the UK and Welsh Governments.

British architecture 1919–39. Book review.

Conservation of listed prefabs in Moseley.

Energy industry calls for urgent reform.

Heritage staff wellbeing at work survey.

A five minute introduction.

50th Golden anniversary ECA Edmundson apprentice award

Showcasing the very best electrotechnical and engineering services for half a century.

Welsh government consults on HRBs and reg changes

Seeking feedback on a new regulatory regime and a broad range of issues.

CIOB Client Guide (2nd edition) March 2025

Free download covering statutory dutyholder roles under the Building Safety Act and much more.